Description

CLASSIFICATION

EN ISO 14341-A; G 38 3 C1 3Si1; Weld Metal; EN ISO 14341-A; G 42 4 M20 3Si1; Weld Metal; EN ISO 14341-A; G 42 4 M21 3Si1; Weld Metal; EN ISO 14341-A; G 3Si1; Wire Electrode; SFA/AWS A5.18; ER70S-6; Wire Electrode; CSA W48; B-G 49A 3 C1 S6; Wire Electrode; JIS Z 3312; YGW 12 (C1); Wire Electrode

APPROBATION

3Y SA; ABS; SA3YM; BV; EN 13479; CE; 42.039.29; DB; III YMS; DNV-GL; 3YS H15; LR; 3YS; PRS; 3Y40MS; RS; 10052; VdTÜV; PV,ZG; B-G 49A 3 C1 S6 (B-G 49A 3 C G6); CWB; ZG; YGW12 (C1); JIS; PV; 1.0-1.6 mm; NAKS/HAKC; ZG; 1.2-1.6 mm; NAKS/HAKC; ZG; 3Y S; RINA; PV; 3Y S; RINA

DIAMÈTRE (mm)

0,8 / 1 / 1,2 / 1,6

EMBALLAGE (kg)

15 / 18 / 200 / 250

GAZ DE BLINDAGE

ISO 14175 and EN 439 M21 : Ar + 15-25% CO2 C1 : 100% CO2

ANALYSE CHIMIQUE

| Mn | CO2 (C1) | 80Ar/20CO2 (M21) | C | Si |

| 1.46 % | <0,01 % | <0,01 % | 0.08 % | 0.85 % |

PROPRIÉTÉS MÉCANIQUES

| Allongement | Condition | Gaz de protection | Limite élastique | Résistance à la traction | Temps de test | Test de température |

| 30 % | As Welded | AWS CO2 (C1) | 430 MPa | 530 MPa | – | – |

| 26 % | As Welded | EN 80Ar/20CO2 (M21) | 470 MPa | 560 MPa | – | – |

| 28 % | Stress Relieved | EN 80Ar/20CO2 (M21) | 370 MPa | 495 MPa | 15 hr | 620 °C |

| 25 % | As Welded | EN CO2 (C1) | 440 MPa | 540 MPa | – | – |

MATÉRIAUX À SOUDER

ASTM

A 139 A 210 Gr A1, C A 36 | A 234 Gr WPB A 334 Gr 1 A 106 Gr A, B, C | A 131 Gr A, B, D API 5LX42 API 5LX46 | API 5LX52 API 5LX60

EN

10113-2 S275, S355, S420 10113-3 S275M, S275ML, S355M, S355ML 10113-3 S420M, S420ML 10025 S185, S235, S275, S355 10208-1

L210, L240, L290, L360

Altri

Fe 360, 430, 510 Acciai gruppo 1 EN 288/3

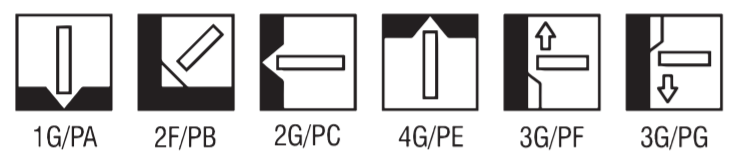

POSITIONS DE SOUDAGE